YC22 Startup Consultation

Introduction

This was a consultation project for a YC22 agri-tech startup through Berkeley Engineering Solutions, a mechanical engineering consulting organization I co-founded. The start-up that my team and I worked with is focused on automating mushroom farming, and the first step in this process is to pauestrize the mushroom feed to elminate all possible

Design Considerations

- Can load and operate with 25kg of substrate

- Has to have a closed system of air that is contamination proof

- Can reach all necessary temperatures for a complete pasteurization cycle

- Room temp to 70C

- Has to operate automatically

- Must be able to run a full cycle with < 5min of human interaction per day per machine

- Must sense compost temperature, air oxygen content, volumetric air flow, and inlet air temp.

- Data should be logged and saved for every trial

- Data collection rate should meet or exceed 4 samples per minute

- Temperature gradient across substrate must be < 2 deg C throughout cycle

- Must be easy to clean and can be completely sterilized between cycles

- Clean time should be < 15min per cycle

- Air flow rate must be adjustable and controllable

- Must be able to reach 500 m^3/hr/ton substrate at maximum

- 13.5m^3/hr or 8cfm

- Must be able to reach 500 m^3/hr/ton substrate at maximum

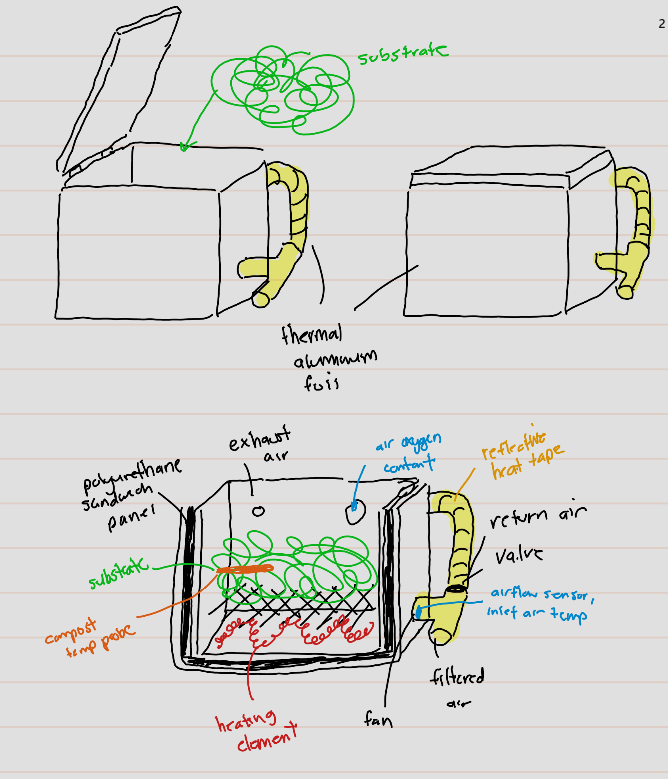

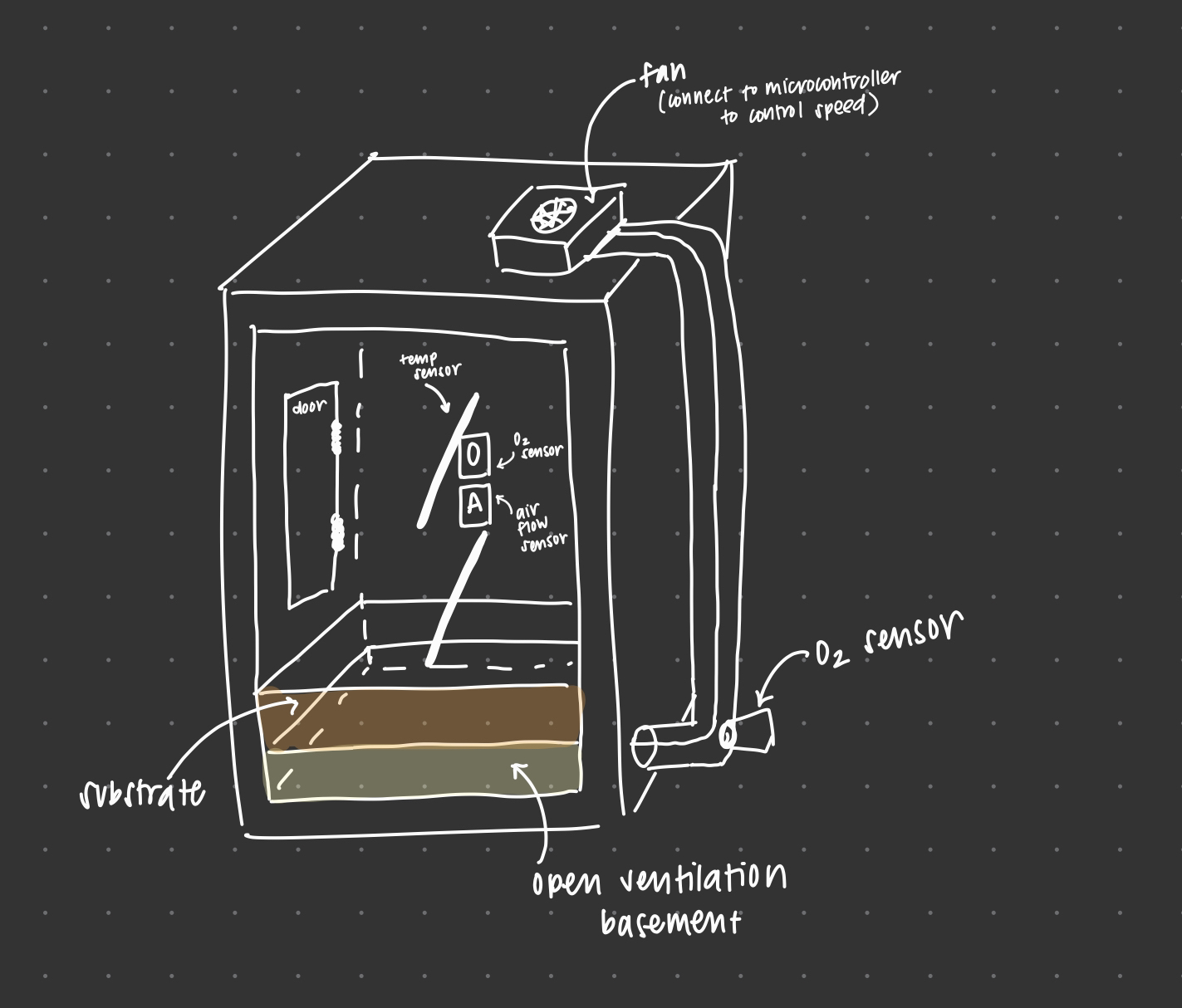

Inital Concepts

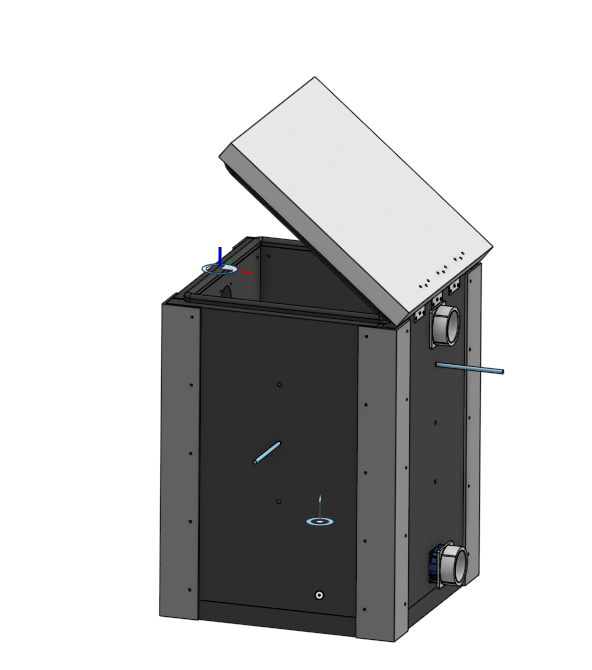

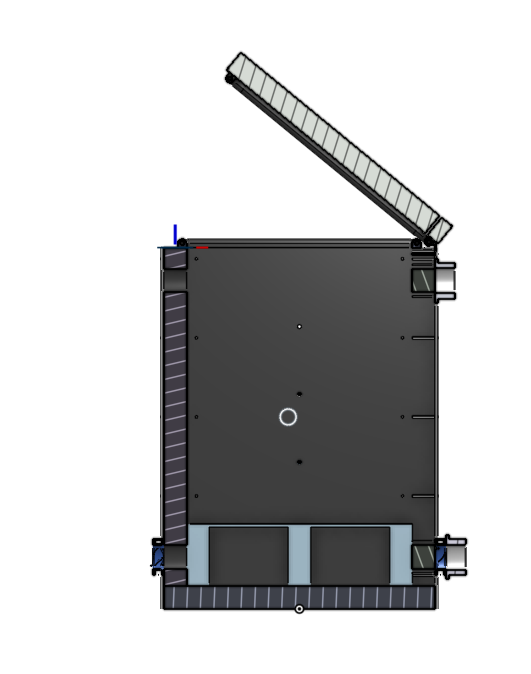

Prototype & Testing

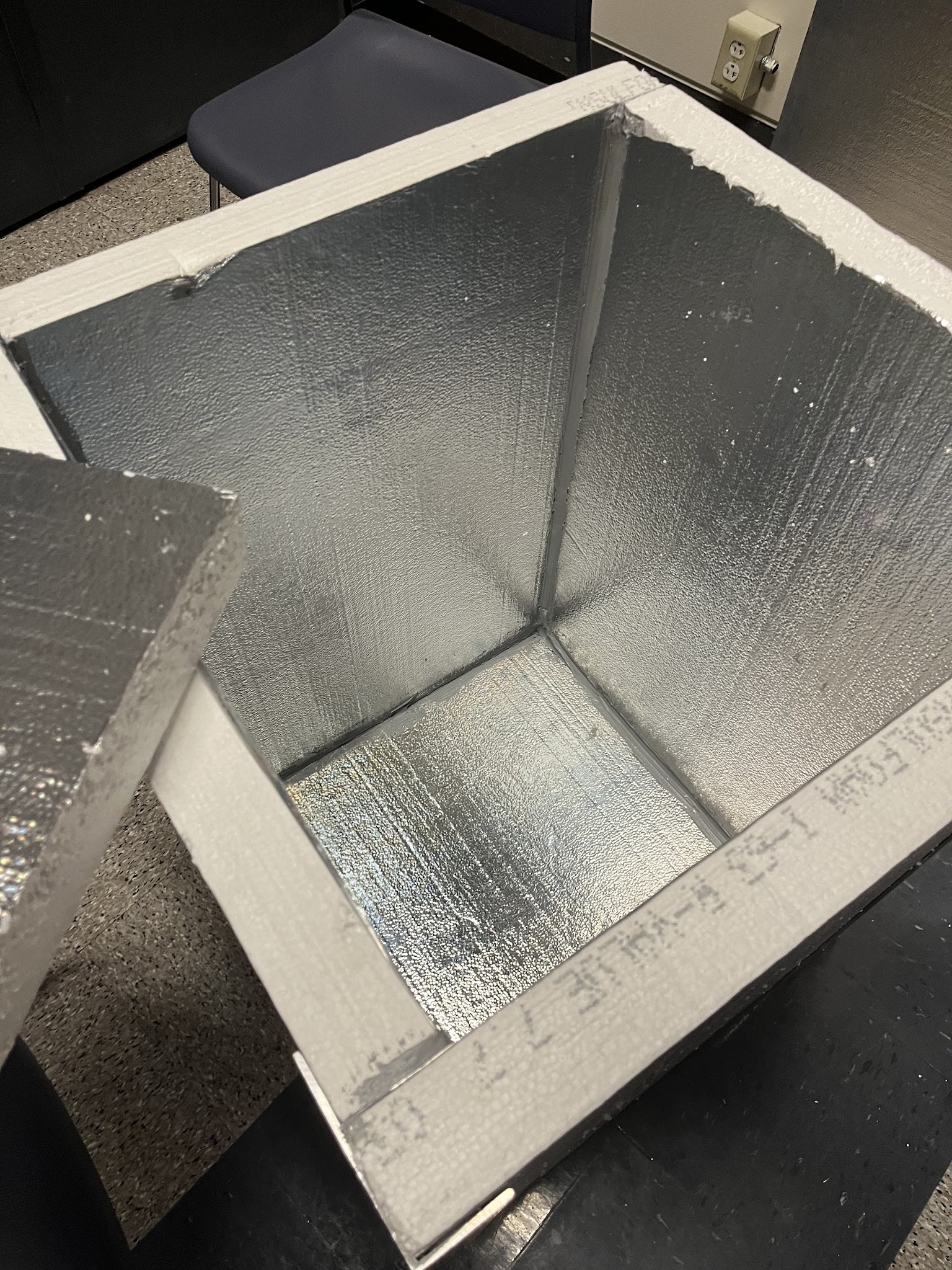

Body Interior

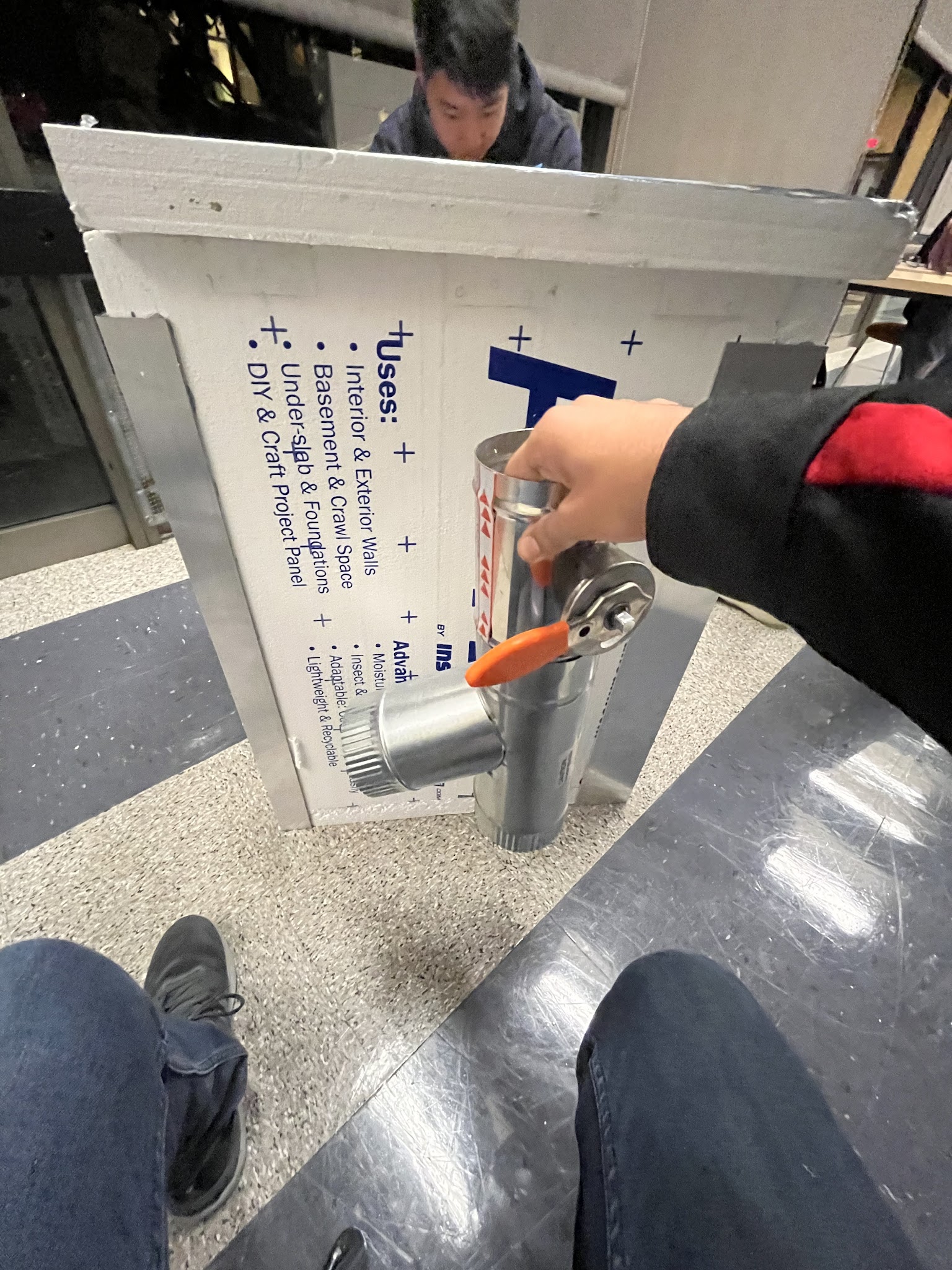

Body Exterior

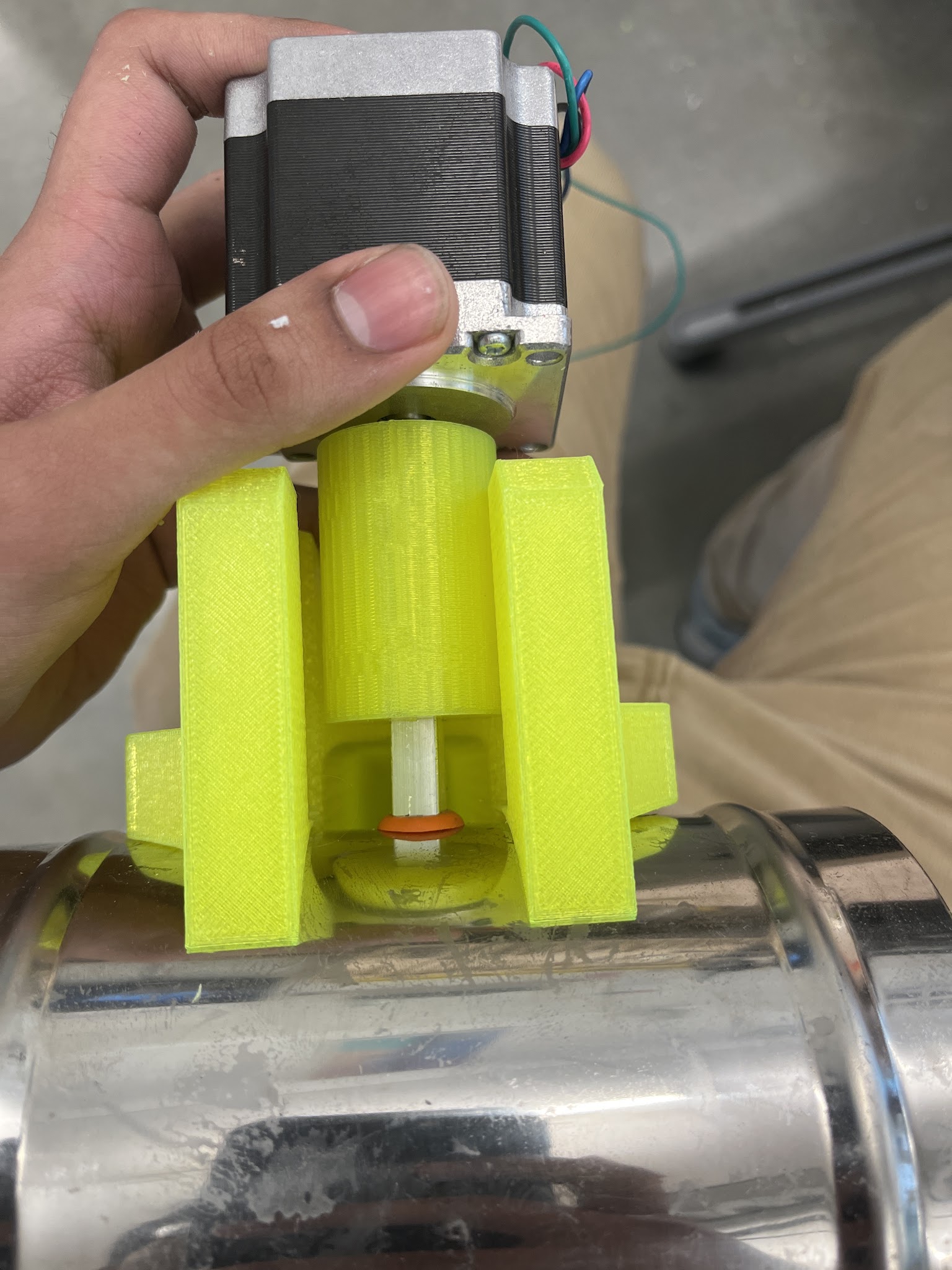

3-D Printed Motor Bracket

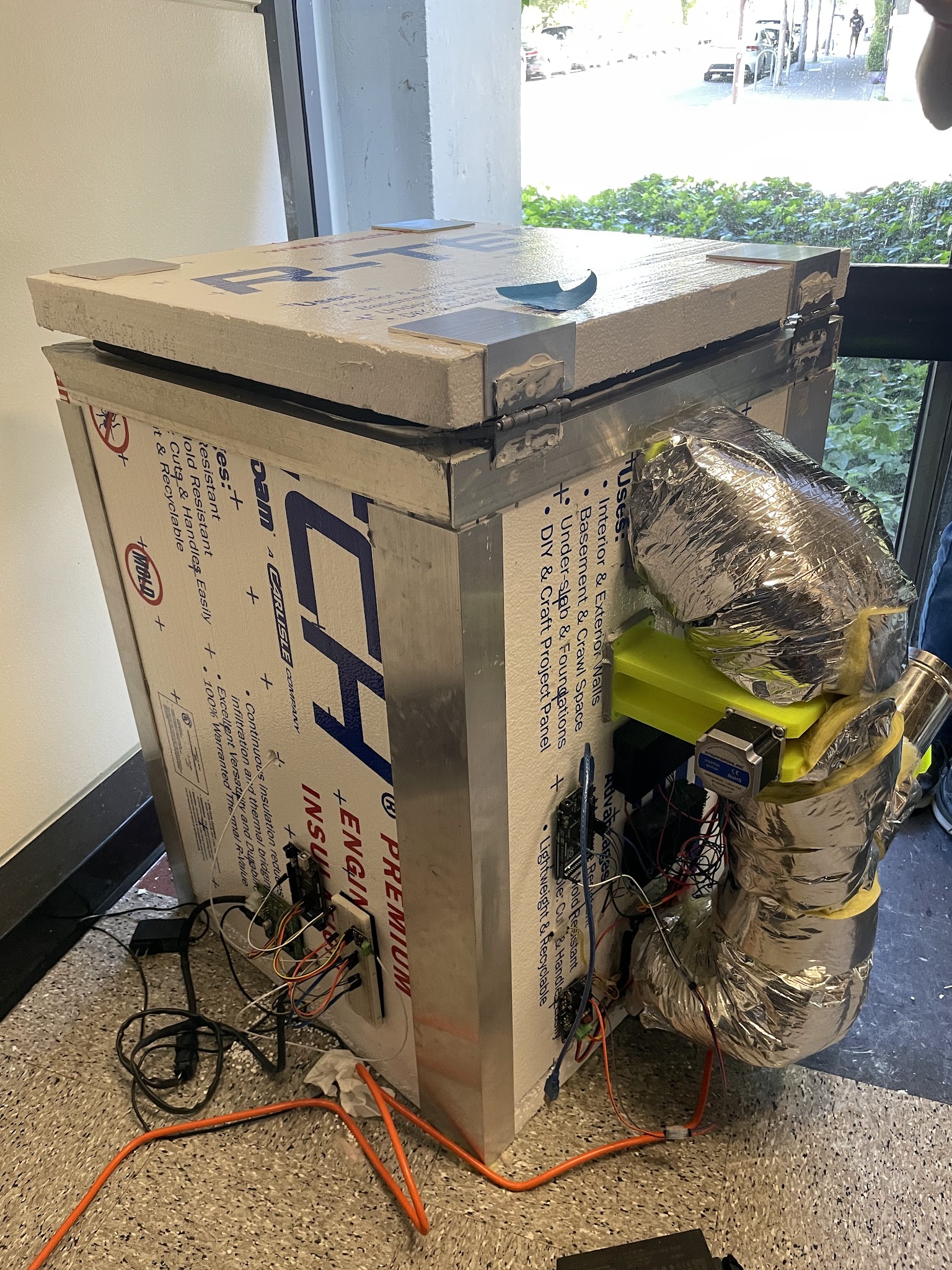

Final Design

Final Product prepped and ready for the full test.

Side view showing the motor controllers, intake fan, and microcontrollers

Reflection

Me and my team were able to run our oven to successfully pasteurize the composts in our first and only test with compost. However, due to an inability to properly tune the PID loops that ensured the oven successfully hit its temperature targets, the oven hit only the first target temperature and held it for the duration of the test instead of performing the multiple heating a cooling cycles it was meant to. Overall this was an immensely enjoyable project as it was the first project where I got the opportunity to apply my knowledge of thermodynamics and implement a PID controller in a more abstract application.